Brother KR230 ribbing attachment works with only one knitting machine: 9 mm -gauge (bulky) Brother KH230.

This post is dedicated to the KR230 ribber I refurbished in my shop.

To learn about the overall pros and cons of Brother KR230 ribbers, refer to my other blog post in my Knitting machine Encyclopedia.

The ribber came without a lot of accessories but I was able to collect most important ones.

Thus, all major accessories will be included with the ribber with the exception of:

- yard tension stand: since the machine I tested did not have the original (to the KH230) tension rod but a generic Brother tension rod, the yarn tension stand was unnecessary. But if you are buying JUST the ribber from me, and your Brother KH230 has the original tension mast, contact me, and I might be able to source the original yarn tension stand for you. I am actually not quite sure why the ribber came with this special yarn tension stand – maybe to create a right angle for the tension mast because it is quite unique and is unlike any other Brother knitting machine tension masts.

- cast on thread: any silky and strong yarn will work

- case for the needles

- Knit leader setting plates: the machine did not come with those. Typically, new knitters new to machine knitting rarely use the knit leader and as a result, these parts get misplaced. If you advance enough to use KH230/KR230 setup with knit leader, these setting plates are available online for a reasonable cost.

- hard copy of the ribber will not be included, but it can be found online. Keep in mind that the manual is written pretty poorly with typos.

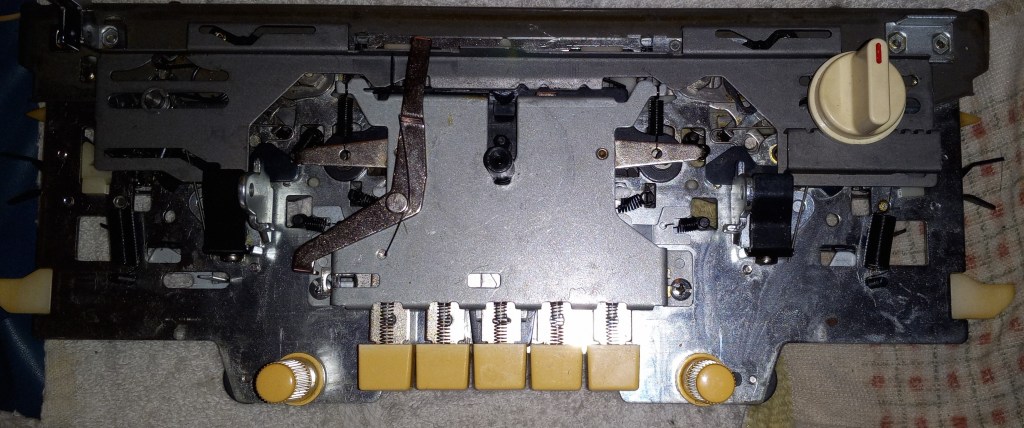

I cleaned the needle bed, and side brackets. I cleaned and inspected all needles individually. Needles in good condition but with some minor rust were polished until they are smooth to touch (however, some discoloration might still be visible but it does not affect the needle functioning). I inspected the carriage and the connecting arm thoroughly too and replaced some broken plastic parts in it.

I included a brand new retaining bar with a brand new sponge.

I am also including new table clamps for the ribber (not shown). All tests were done with these table clamps (incorrect table clamps can create an incorrect angle between the main and the ribber beds and cause misalignment and, as a result, missed/dropped stitches).

The cast on combs that came with the ribber are in great shape.

I also sourced out completely new setting plates for KR230. Notice that the setting plates are asymmetric, unlike settings plates for all other ribbers.

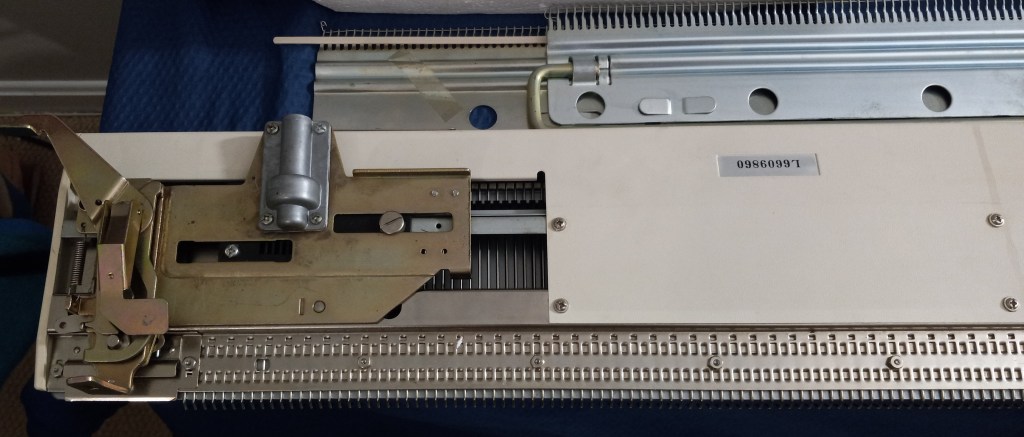

One feature that I like about the KR230 ribber is that there are markings on the needle bed for the working position (position B) of the needles.

I serviced and oiled the connecting arm to ensure that the wheel inside it moved freely as it is responsible for the indicator arros as well as for lifting the pressers to assist with pushing the stitches down.

To ensure all needles knit properly as well as other are no hidden problems, I knitted on 20-30 needles as well as on all neeldees using several different yarns: acrylic sport-weight yarn, double-thread worsted-thickness acrylic-wool blend yarn, and a mohair-blend with Lurex thread in it. The machine handled all the yarns like a champ!

These tests are shown in my video. Prior to the tests, I made sure the distance between the needlebeds was adjusted to the optimum to ensure no missing stitches during the cast one and further one.

Below are the finished projects made from the panels knitted on Brother KH230/KR230 setup using the two out of three yarns I mentioned above.

Let me know what you think.

The ribber does not come with its original packaging. It will very likely be shipped in two different packages – long one for the needle bed and a smaller one (in size) for all other parts.

Below are the pros and cons of the Brother KR230 ribber I serviced in my shop (to read overall pros and cons of Brother KR230 ribber, refer to my Knitting Machine Encyclopedia):

PROS:

- easy to set up

- takes a variety of yarns (thickness- and texture-wise)

- comes with all major accessories

CONS:

- some minor accessories are missing (see above); however, their absence does not affect the functioning of the ribber.

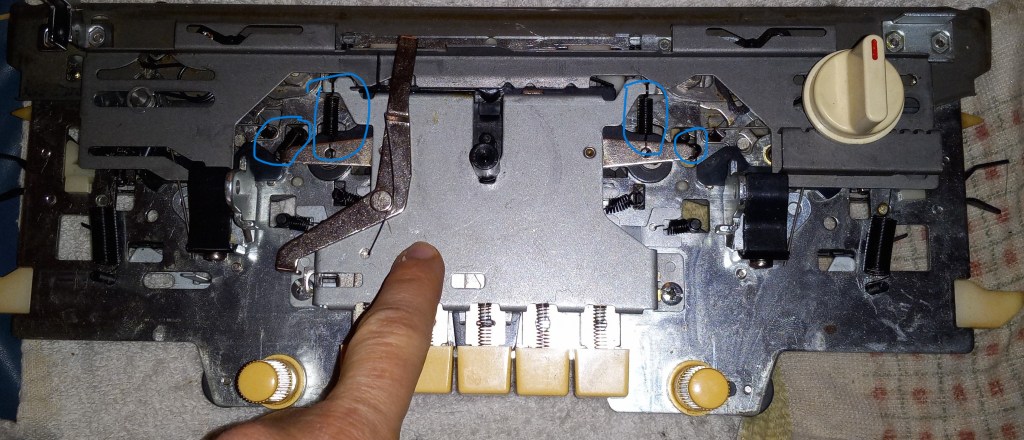

- The part of the side bracket that gets inserted into the machine on the left-hand side was a bit bent and I straightened it. (The top surface of that section has scratches as a result of my strainitening it). The series of pictures below shows that bracket and that area from different angles. Again, it did not affect setting up the machine but the bracket needs to be pushed in with a bit more force than the other one. Just something to keep in mind when connecting the ribber to the main bed.

As you can see, I invested a lot of both time and money into this ribber to ensure it has all accessories and that it functions well before I pass it on to other knitting machine enthusiasts.

Brother Profile KH500 Knitting machine is a lightweight machine with manual-only needle manipulation capability. It looks very similar to 4-push button machine, like Profile KH 551. But since it has a more advanced row counter, I assumed that it was manufactured after it – maybe in the very early 1970-ies. A could not find any specific information anywhere on the web or in printed brochures. Other indications that this machine was a later but simplified version of push-button machines is KH500 still has slots for the extension rail (but does not come with the lace carriage) and slots to attach a ribber. The original cardboard box still shows the older version of the row counter….

Brother Profile KH500 Knitting machine is a lightweight machine with manual-only needle manipulation capability. It looks very similar to 4-push button machine, like Profile KH 551. But since it has a more advanced row counter, I assumed that it was manufactured after it – maybe in the very early 1970-ies. A could not find any specific information anywhere on the web or in printed brochures. Other indications that this machine was a later but simplified version of push-button machines is KH500 still has slots for the extension rail (but does not come with the lace carriage) and slots to attach a ribber. The original cardboard box still shows the older version of the row counter….

.

.

This machine is simple but offers tremendous potential for those who want to continue to feel the satisfaction of knitting manually. This machine is excellent for those transitioning from hand-knitting to machine knitting, for those who are not quite ready to give up control over stitch manipulations to the machine, for those who like simple knits but can’t quite get the stitches even, and for fiber artists.

This machine is simple but offers tremendous potential for those who want to continue to feel the satisfaction of knitting manually. This machine is excellent for those transitioning from hand-knitting to machine knitting, for those who are not quite ready to give up control over stitch manipulations to the machine, for those who like simple knits but can’t quite get the stitches even, and for fiber artists.

The two round pillars to screw the handle onto the carriage are a bit discolored. I decided not to polish it not to remove even more of a protective coating. The handle still crews on without problems.

The two round pillars to screw the handle onto the carriage are a bit discolored. I decided not to polish it not to remove even more of a protective coating. The handle still crews on without problems.

KnitKing Simple seven is a plastic flatbed knitting machine. It is also known as Brother KX350.

KnitKing Simple seven is a plastic flatbed knitting machine. It is also known as Brother KX350. It packs nicely into an original box with the styrofoam pieces cut out for all the parts so there is no confusion about where each part goes. The box is a bit beat-up but still holds everything nicely.

It packs nicely into an original box with the styrofoam pieces cut out for all the parts so there is no confusion about where each part goes. The box is a bit beat-up but still holds everything nicely.

Studio SRN321 ribber is an attachment that allows alternating knit and purl stitches. It was released in 1972. The ribber has 200 needles. Studio SRN321 ribbing attachment fits the following knitting machines: Singer/Studio 321, as well as models MOD. 315, 313, 312 and 305. SRN321 ribber adds so many patterning possibilities, as mentioned in the instructions and beyond. I did not see in the instructions if this ribber can provide double jacquard possibilities and I did not test it myself yet.

Studio SRN321 ribber is an attachment that allows alternating knit and purl stitches. It was released in 1972. The ribber has 200 needles. Studio SRN321 ribbing attachment fits the following knitting machines: Singer/Studio 321, as well as models MOD. 315, 313, 312 and 305. SRN321 ribber adds so many patterning possibilities, as mentioned in the instructions and beyond. I did not see in the instructions if this ribber can provide double jacquard possibilities and I did not test it myself yet.