Brother KX350 knitting machine is a plastic flat needlebed machine with 130 needles, positioned 7 mm apart. The article below is dedicated to the machine I serviced and tested in January 2024. If you want to know the pros and cons of the Brother KX350 knitting machine mode, read my Knitting Machine Encyclopedia.

On this machine, I cleaned and inspected all needles. I cleaned the needle bed and the carriage. I inserted a new needle-retaining sponge.

The machine will come with all assesories shown in the manual.

The tapestry needle will be plastic. The oil in the bottle that came with this machine still looks good (transparent and not yellow), so it will be included as well but there is only half a bottle left. I recommend purchasing Hoppe’s Elite Gun Oil

However, the hard copy of the manual will not be included but it is available online for free.

To ensure that all functions of the carriage work well, I first knitted a swatch (with a pretty thick yarn – two strands of 50 g/150 m (1.76 oz/109 yards) per skein- all went well (watch the vidhttps://youtu.be/ANFTFSCiwqseo).

After a successful swatch (knitted with a relatively thick yarn), I proceeded (with the same yarn) on a full bed (all needles) to test whether all needles formed nice stitches without unprompted tucking. All tests went well – watch a video of my tests.

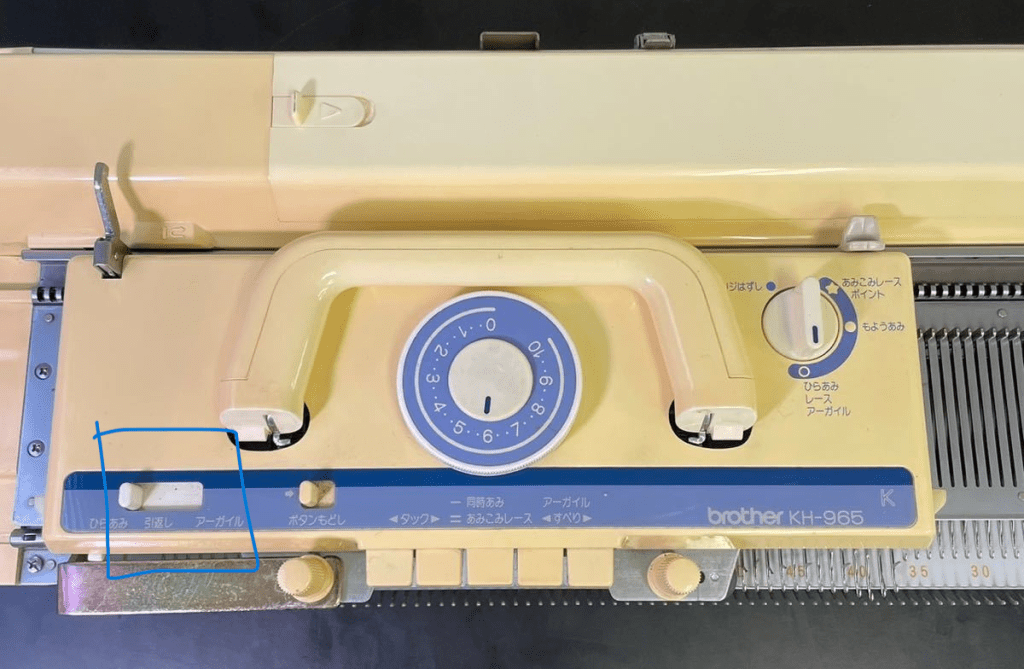

All levers, knobs, and buttons move freely on the carriage (it is demonstrated in my full video). I also knitted using the HOLD and PART functions of the carriage.

When I test my machines, I like to learn something new in terms of knitting, come up with a new design or test a new feature of the machine.

So, this time, I came up with my own pattern for a large dog sweater and I knitted it. I used the partial knitting function, HOLD position functions, mock ribbing, and cast-off. The picture below shows my (unfortunately, unhappy) model who will be wearing her new sweater. There are a couple of design flaws that I will be improving but while the next beta version is in progress, this one will keep my dog belly warm. Check out this booklet for lots of other patterns possible to make on this machine.

A couple of imperfections of this machine:

There are really no flaws. However, I wanted to mention that no original box came with this machine but it will come well-packed for shipping.

No hard copy of the manual is a bummer but this machine is easy to use and straightforward and with the hints provided by the manual online, new knitters should have no problems starting using KX350.

Overall, Brother KX350 is not only a perfect machine for beginning machine knitters, but for experienced knitters too: KX350 takes thick yarn and can be a quick tool to test a pattern (like I did with the dog sweater).