Singer HK100 plastic flat-bed knitting machine was made in 1983 to supply hobbyists with less expensive and simpler knitting machines. Indeed, it is extremely easy to set up and is almost intuitive to use. It still can produce a lot of nice garments with a variety of yarns. I personally tested some cotton yarns, acrylic (Red Heart – shown in my video), and the worsted wool blend. This machine is excellent for beginners who are just trying to get a feel for what machine knitting is like.

Singer HK100 plastic flat-bed knitting machine was made in 1983 to supply hobbyists with less expensive and simpler knitting machines. Indeed, it is extremely easy to set up and is almost intuitive to use. It still can produce a lot of nice garments with a variety of yarns. I personally tested some cotton yarns, acrylic (Red Heart – shown in my video), and the worsted wool blend. This machine is excellent for beginners who are just trying to get a feel for what machine knitting is like.

Singer HK100 is considered a mid-gauge/bulky knitting machine. It contains 120 needles and is capable of only manual stitch and needle manipulation to create various patterns, like, tuck, slip, fair isle, cables, lace, etc. However, there are so many youtube tutorials and printed patterns that the possibilities are endless.

The machine has a unique brown/white color combination, which makes this machine very distinguishable.

What I found especially user-friendly is the yarn guide/tension mast. It simply inserts into the carriage while the yarn cone or cake is positioned on the floor. The reason I find it newbie-friendly is that even seasoned machine knitters sometimes struggle with the metal tension masts on more advanced knitting machine models. Additionally, when I knit on my flat beds, I typically don’t lift my head up to see what’s going on with the yarn on the mast and sometimes there are sudden stops if the yarn tangles. In the case of HK100 and the yarn being right in front of you, you will always see what is happening with it and you can easily catch the knots before they choke your carriage. In fact, my video shows that there was a knot in the yarn, I caught as it was about to enter the carriage, untangled it, and then continued knitting without problems. I was very pleased that I fixed the problem on the go.

I also liked very much the intuitiveness of this machine. For example, when I was a newbie on my metal flatbed machines, I always had to look in the manual as to what the position of the levers meant; what I need to do to simply slide the carriage without knitting. On Singer HK100 there are not that many levers and the only function of the levers on the side of the carriage is to NOT KNIT 😊 You will see in my video that after I made a mistake, I simply pressed the lever and slid the carriage out of the way without knitting.

Another interesting observation I made with this model is that it handles knots without too much drama 😊 Here is what I mean by that: during one of my tests, my worsted wool blend tangled a bit and formed a small loose knot. It passed through the carriage so easily that I only saw the knitted-in knot after 10 (or so) rows. On one side, I was pleased because in my other machines, a knot in the yarn means a tighter row, breakage, sudden stop… But in this case, the knot became part of the knitted fabric. In fact, the knitted-in know was visible only on the wrong side but not on the right side.

Another interesting observation I made with this model is that it handles knots without too much drama 😊 Here is what I mean by that: during one of my tests, my worsted wool blend tangled a bit and formed a small loose knot. It passed through the carriage so easily that I only saw the knitted-in knot after 10 (or so) rows. On one side, I was pleased because in my other machines, a knot in the yarn means a tighter row, breakage, sudden stop… But in this case, the knot became part of the knitted fabric. In fact, the knitted-in know was visible only on the wrong side but not on the right side.

Below are the specifics on the machine, I cleaned and tested and offering for sale here and in my Etsy store:

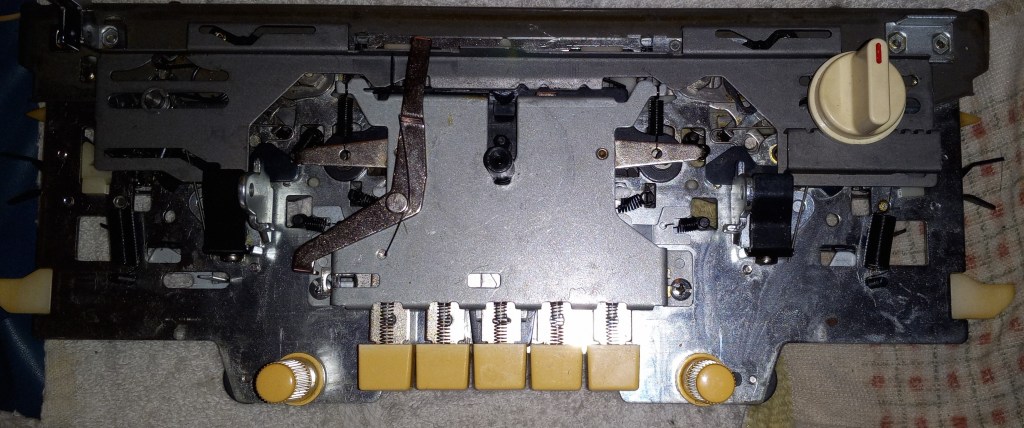

When I just took the machine out of the box (which looked like it was the original box), it looked like it was never used. However, it was dusty. I took out all the needles and cleaned and inspected each individually. I removed the sponge bar, cleaned the “canal” for it inside the machine (right under the flatbed), and inserted a new sponge bar. (Video on how to remove a retaining for inspection, or for a needle change bar is here.

The machine comes with all major assesories, a hard copy of the manual, and three brochures on how to knit various things (all in excellent, barely-use, like-new shape).

A couple of minor things missing are:

The fact that all these minor assesories are missing, does not affect how the machine works.

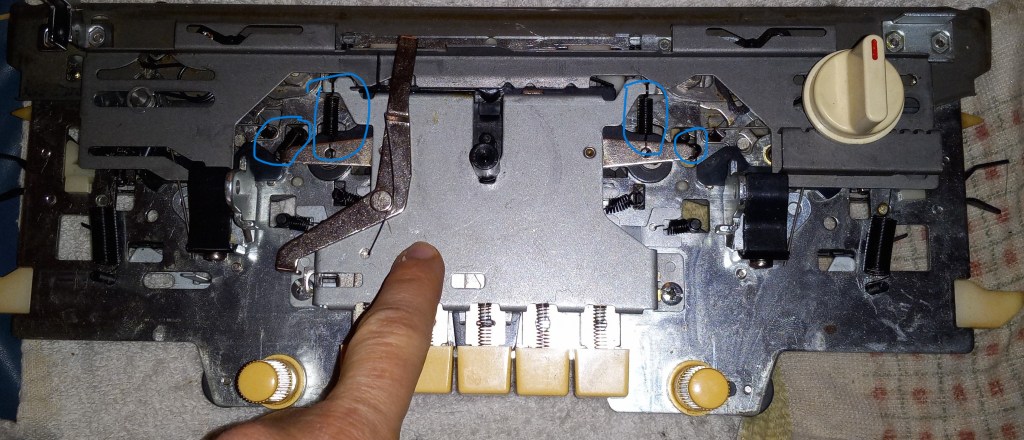

One missing part that I had to fix is a row counter tripper. The machine arrived to me without it. I glued a yellow piece of plastic shown below and it stayed throughout my whole testing.

To make sure it does not break again, I packed it with lots of bubble wrap. Other solutions are possible as well (for example, inserting an L-shape piece of plastic into one of the slots on the back of the carriage).

I recorded a video of almost all the tests I ran on this machine. The knitted fabrics were converted into a colorful cowl/neck warmer, and a set of matching scarf, and a slouchy hat.

A favor: please, comment on the blanket in the background. Apparently, I used it without my son’s permission and I am now in trouble. But if he hears from my readers how cute his favorite blanket is (it is his camping blanket), I might be forgiven 😊)

Singer HK100 plastic flat-bed knitting machine was made in 1983 to supply hobbyists with less expensive and simpler knitting machines. Indeed, it is extremely easy to set up and is almost intuitive to use. It still can produce a lot of nice garments with a variety of yarns. I personally tested some cotton yarns, acrylic (Red Heart – shown in my

Singer HK100 plastic flat-bed knitting machine was made in 1983 to supply hobbyists with less expensive and simpler knitting machines. Indeed, it is extremely easy to set up and is almost intuitive to use. It still can produce a lot of nice garments with a variety of yarns. I personally tested some cotton yarns, acrylic (Red Heart – shown in my  Another interesting observation I made with this model is that it handles knots without too much drama

Another interesting observation I made with this model is that it handles knots without too much drama